Innovation in construction often means asking tough questions and pushing the boundaries. The question we asked ourselves was:

"Can we solve the problems of traditional ICF?"

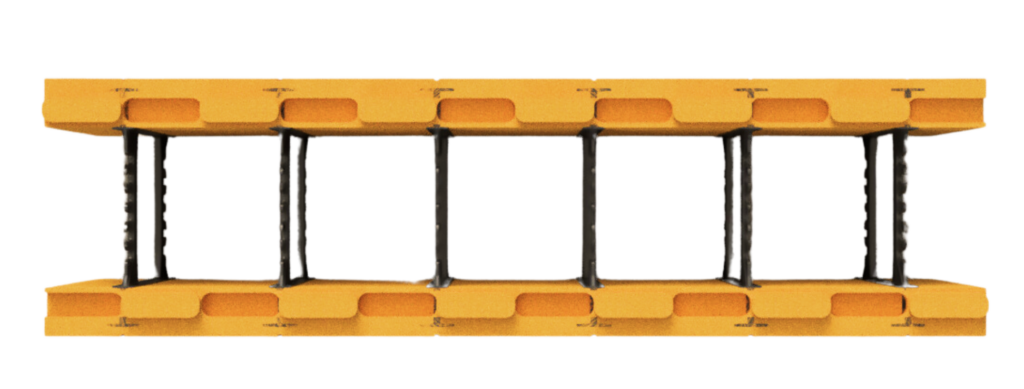

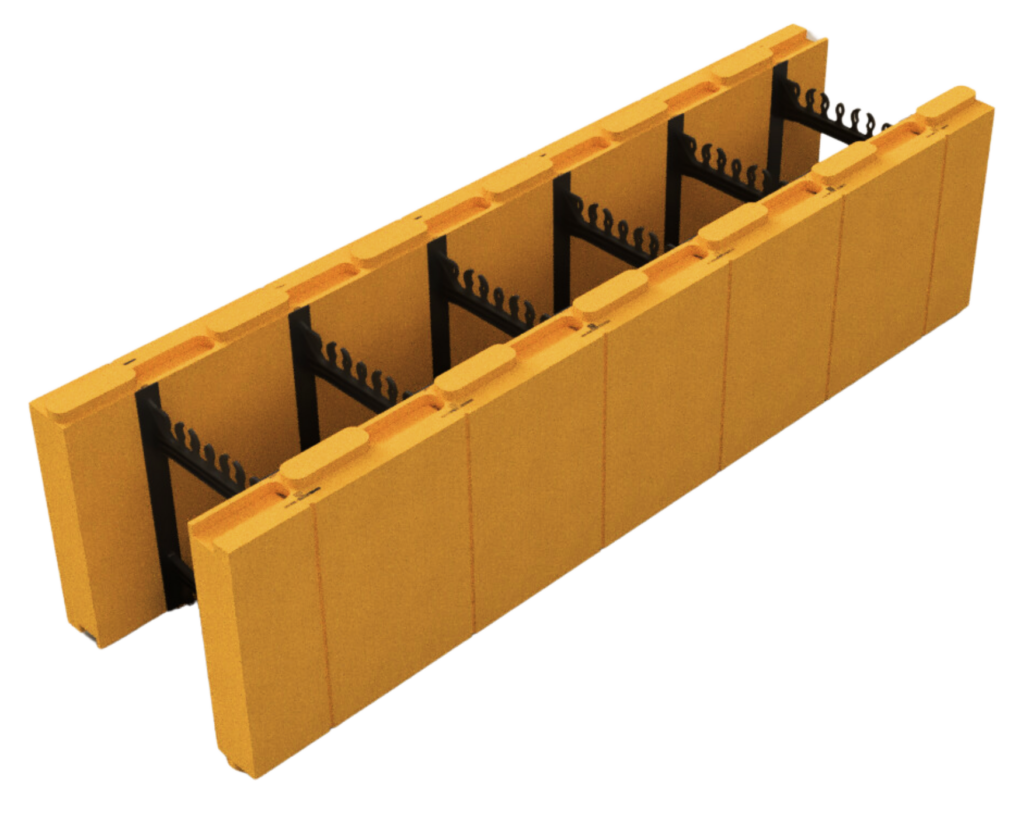

Polyurethane is widely recognized in aerospace and various construction applications for its superior strength, true closed-cell structure, and fire resistance. It is used extensively in insulation, sealants, and coatings. However, despite its advantages, its application in ICF has never come to fruition.

We saw the potential to revolutionize the construction market by integrating polyurethane.

So, we looked to the sky and developed a superior product.

POLYURETHANE

A Material Built for Extremes

SUPERIOR INSULATION AND STRENGTH:

Polyurethane foam played a crucial role in the Space Shuttle program. NASA engineers used it to insulate the external fuel tank, protecting it from the extreme heat of lift-off while keeping the cryogenic fuel at -423°F. This foam provided structural integrity, lightweight properties, and excellent insulation, all essential for withstanding the force of a rocket launch.

LIGHTWEIGHT AND DURABLE:

Rockets, like those used by SpaceX, incorporate polyurethane, among other advanced materials, to achieve a lightweight yet durable structure. The Falcon 9 rocket, for example, uses a combination of aluminum, titanium, and polyurethane to balance strength and weight, essential for achieving the necessary thrust and efficiency for space travel.

THERMAL AND STRUCTURAL EFFICIENCY:

Polyurethane is also used in rockets because it forms a seamless, self-adhering layer that provides thermal protection and structural support. This helps maintain the integrity of the fuel tanks and other critical components under extreme conditions, such as the thermal loads during re-entry and the mechanical stresses during launch.

Meet the Founders

Kirk Tyler, Founder of Monolith ICF

Monolith’s original founder, Kirk Tyler, embarked on a transformative journey early in his 50-year construction career. Driven by a passion for high-quality outcomes, he was always on the lookout for new products and innovative systems. Introduced to Insulated Concrete Forms (ICF) in 1994, Kirk recognized their potential for enhancing structural longevity and strength. This began his decades-long deep dive into ICF technology.

Over the years, Kirk has led numerous ICF projects, ranging from modest homes to luxury buildings. He has even overseen the construction of 17 LDS Church Temples worldwide. His most ambitious endeavor, the BYU Hawaii Student Housing project, is on track to become the largest ICF project ever developed.

Throughout his extensive experience with ICF construction, Kirk’s pursuit of superior building materials intensified. The BYU Hawaii project underscored the limitations of traditional polystyrene-based ICFs, prompting Kirk to seek significant improvements in an industry that had reached an innovation plateau. As a result, in 2016, Kirk began collaborating with industry professionals to develop a polyurethane-based ICF. Despite the success of the product design, challenges emerged with a misalignment between Kirk and his partner.

Later, his interest was piqued when he received a message from Ben, who had been on his own quest to find or design better building systems since 2019. Ben expressed unwavering confidence in the product’s potential and a shared vision. His steadfast commitment resonated with Kirk, leading to a partnership offer and the decision to rebuild the company from scratch.

Since then, Kirk and Ben have united to develop a superior product and establish a company grounded in integrity, innovation, and genuine care for people. These foundational principles ignited Kirk’s journey from the outset.

Ben Snuffer, Co-Founder of Monolith ICF

In 2019, co-founder Ben Snuffer embarked on a mission to create a home that tackled common issues plaguing standard construction. His background in remodeling smaller homes and apartments gave him firsthand insights into the hidden but rampant flaws of common building systems. From concealed leaks and poor craftsmanship to termites and mold problems to unnecessarily high utility expenses, Ben knew well the true costs of outdated building methods.

These experiences instilled in him a deep appreciation for solid construction, quality building materials, and superior long-term planning. He wanted homes protecting people and their investments, so he decided to discover or design just that.

Over the years, Ben’s journey eventually led him to ICF construction. Impressed by the long-term possibilities of this building method, Ben wondered how far these benefits extended. Researching the problems associated with each ICF company’s designs, he came across a tiny, local venture that was shockingly different from the big-name corporations. They used a special material – unique from all other ICF blocks – well known for its superior strength, durability, and insulative properties in other applications. Because Ben had experience with this material, he immediately recognized what an incredible, life-changing product this could be.

Fueled by his excitement, Ben tirelessly pursued contact with the company. After months of persistence via phone, email, and even through a dormant Facebook page, he finally connected with a key figure. Ben’s enthusiasm reignited the passion of co-founder Kirk Tyler – the original creator of Monolith’s ICF blocks. While Ben sought an opportunity to utilize the product finally, Kirk instead recognized someone who shared his core values and ultimate vision for Monolith. Today, they are establishing a new benchmark in construction by raising standards in quality, energy efficiency, longevity, strength, and overall building excellence.

Our Story

Kirk Tyler, driven by a deep commitment to excellence in his construction career, discovers ICF construction. His relentless pursuit of producing the best quality work guides this pivotal shift.

With thirty years of ICF experience, Kirk embarks on developing an advanced ICF block. Using a superior material with a strong reputation in the construction industry, he weaves together two proven concepts to create a groundbreaking system for building resilient, energy-efficient structures.

Ben discovers Kirk's polyurethane ICF online and is instantly impressed. After months of trying to contact the company, Ben finally connects with Kirk, who had been out of touch for nearly two years. They quickly become friends and decide to rebuild the company together from the ground up.

Over the next two decades, Kirk leads numerous significant projects, including constructing 17 LDS church temples and the expansive BYU Hawaii Student Housing project. This housing project is set to be the largest ICF project ever developed, highlighting Kirk's expertise and dedication to the field.

Kirk’s innovative ICF block excels in both testing and client use. However, despite the product’s success, his partnership at the time falters due to conflicting values, presenting significant challenges.

The team is strengthened with Jeff Savage, Ph.D., and Jason Myers, who bring valuable business expertise. They raised an investment round to further develop the ICF block, aiming to reopen production later this year in the Salt Lake Valley.