Construction methods have remained largely unchanged for decades, with many builders relying on traditional materials despite their known limitations. However, the material science behind Monolith’s polyurethane Insulated Concrete Forms (ICF) represents a significant advancement that addresses many longstanding challenges in the construction industry. While our previous blog explored the practical benefits of the 7-in-1 Building System, this article examines the material properties that make these benefits possible.

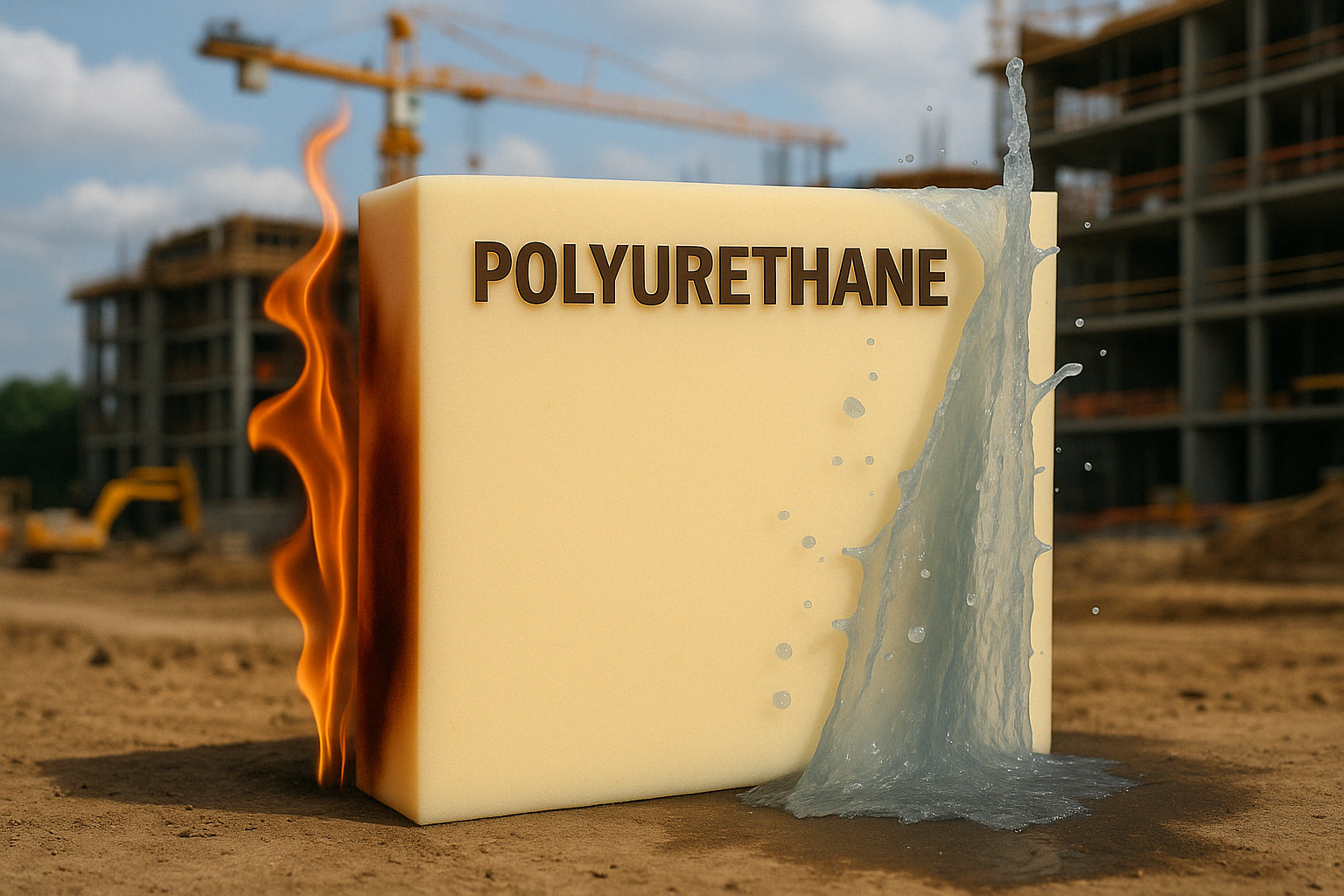

Beyond EPS: Why Polyurethane Changes the ICF Equation

The ICF industry has historically relied on expanded polystyrene (EPS) for forms. While this approach improved upon traditional construction in many ways, EPS has inherent limitations that polyurethane directly addresses.

ICF Material Comparison

| Property | Traditional EPS ICF | Monolith Polyurethane ICF | Practical Impact |

| Compressive Strength | 15-25 psi | 25 psi | 1.8x stronger, reducing damage during installation and concrete pouring |

| Water Absorption | 2.95% by volume | 1.1% | Eliminates moisture-related problems including mold and reduced insulation performance |

| R-Value per inch | 3.6-4.2 | 6-7 | Superior thermal performance with thinner walls |

| Fire Resistance | Will melt and contribute to flame spread | Class 1/A fire-rated with 3+ hour resistance | Enhanced safety and reduced fire insurance premiums |

| Pest Resistance | Attractive to termites and rodents | Naturally resistant to pests | Eliminated need for chemical treatments and reduced long-term maintenance |

| Weight | Similar to polyurethane | Lightweight yet durable | Easier handling, less worker fatigue, faster installation |

| Structural Integrity | More brittle, prone to breakage | Flexible yet strong | Fewer damaged forms, less waste, more consistent pours |

The Chemistry Behind Polyurethane Performance

Polyurethane’s superior performance stems from its molecular structure. Unlike EPS, which consists of expanded polystyrene beads with air pockets, polyurethane is a closed-cell foam created through a chemical reaction between polyol and isocyanate. This reaction creates a rigid polymer with millions of tiny, enclosed cells that:

- Trap air more effectively – The closed-cell structure prevents air movement through the material, enhancing insulation performance

- Block moisture completely – Each cell is fully enclosed, preventing water migration

- Create structural stability – The cross-linked polymer chains provide excellent dimensional stability

- Distribute force evenly – The material flexes slightly under pressure rather than cracking

NASA recognized these properties decades ago, choosing polyurethane to insulate the external fuel tanks of the Space Shuttle. This same material technology now protects homes and buildings through Monolith’s innovative application in construction.

Material Resilience in Real-World Conditions

Building materials must perform under extreme conditions, not just in laboratory tests. Polyurethane ICF has demonstrated remarkable resilience across various challenging environments:

Extreme Temperature Performance

Traditional building materials often suffer significant performance degradation in extreme temperatures.Polyurethane maintains its insulative properties in extreme cold and can endure short periods of up to 250°C (482°F) without degradation.

- No thermal cycling damage common in other insulation materials

- Consistent R-value regardless of seasonal temperature extremes

- No shrinkage or expansion that compromises air and moisture barriers

- Maintained structural integrity in freeze-thaw conditions

Water and Moisture Resistance

Perhaps polyurethane’s most significant advantage is its water resistance. With its almost zero water absorption, Monolith ICF blocks:

- Maintain full R-value even in high humidity environments

- Eliminate the risk of mold growth within wall systems

- Prevent freeze-thaw damage that affects many building materials

- Create a continuous moisture barrier without additional membranes

- Resist flood damage better than any conventional building material

Fire Performance Testing

In controlled burn tests conducted by independent laboratories, Monolith’s polyurethane ICF demonstrates exceptional performance:

- Achieves Class 1/A fire rating (ASTM E84)

- Maintains structural integrity during 4+ hour fire exposure when combined with concrete

- Does not contribute to flame spread

- Unlike EPS, does not melt or produce toxic smoke

- Creates a significant fire barrier that protects occupants and contents

This performance translates to enhanced safety and potential insurance premium reductions for building owners.

Sustainability Considerations of Polyurethane ICF

Beyond performance, modern construction materials must also address environmental concerns. Monolith’s polyurethane ICF offers several sustainability advantages:

Energy Efficiency and Carbon Footprint

While all construction materials require energy to produce, the lifetime energy savings from polyurethane ICF far outweigh its embodied energy:

- Buildings using Monolith ICF typically use 30-40% less energy for heating and cooling

- Over a 50-year building lifespan, this translates to approximately 150 tons of carbon emissions prevented per home

- The superior insulation performance reduces HVAC equipment sizing by up to 50%, further reducing resource consumption

- The durability and longevity of polyurethane buildings reduce the need for replacement and renovation

Resource Efficiency in Construction

The material properties of polyurethane ICF directly contribute to more efficient resource use during construction:

- Lightweight yet durable forms reduce transportation energy and emissions

- Near-zero waste during installation (compared to 5-10% waste with EPS forms)

- Reduced concrete waste due to fewer blowouts and form failures

- Significantly less water used in construction due to controlled concrete placement

- Fewer damaged materials requiring replacement

Long-term Environmental Benefits

The environmental benefits extend throughout the building’s lifetime:

- Extended building lifespan reduces long-term resource consumption

- Reduced maintenance requirements lower ongoing material inputs

- Superior moisture control prevents mold-related issues and associated remediation

- No chemical treatments needed for pest control

- Potential for recycling at end of building life

Material Integration: How Polyurethane Enhances the Entire Building System

The material properties of polyurethane create synergistic effects with other building components:

Concrete and Polyurethane: A Perfect Partnership

While the polyurethane forms provide insulation and other benefits, the concrete core delivers structural strength. Together, they create several advantages:

- The polyurethane creates an ideal curing environment for concrete, enhancing its final strength

- The permanent bond between concrete and polyurethane eliminates thermal bridging completely

- Concrete’s thermal mass works in concert with polyurethane’s insulation to stabilize indoor temperatures

- The combined system creates exceptional structural rigidity while maintaining disaster resistance

Interface with Other Building Components

Monolith’s polyurethane ICF system is designed to work seamlessly with other building elements:

- Direct Attachment Capabilities: The embedded attachment points allow for secure connection of interior and exterior finishes without special fasteners or techniques

- HVAC Integration: The superior insulation and airtightness simplify HVAC design and reduce equipment sizing

- Plumbing and Electrical: Chases can be easily formed in the polyurethane before concrete placement

- Roofing Systems: The solid concrete core provides exceptional anchoring for roof systems, enhancing wind resistance

- Windows and Doors: The dimensional stability of polyurethane ensures openings remain square and properly sized

Construction Site Advantages of Polyurethane ICF

The material properties of polyurethane translate to practical benefits on the job site:

Handling and Installation

Contractors consistently report several advantages when working with Monolith’s polyurethane ICF:

- Greater flexibility allows for adaptation to slight irregularities in footings

- Better dimensional stability ensures straight, plumb walls with minimal bracing

- Resistance to site damage reduces waste and rework

- All-weather workability extends the construction season

Concrete Placement Benefits

The superior strength of polyurethane provides significant advantages during concrete placement:

- Higher compressive strength allows for faster pours with less risk of blowouts

- Reduced form movement during pouring results in straighter, more predictable walls

- Better vibration tolerance permits thorough concrete consolidation without form damage

- Zero water absorption ensures consistent water-to-cement ratio throughout the pour

- Enhanced thermal insulation creates ideal concrete curing conditions in any weather

The Future of Building Materials: What’s Next for Polyurethane ICF

The construction industry continues to evolve, with several emerging trends that align with polyurethane ICF technology:

Evolving Building Codes

As building codes increasingly emphasize energy efficiency, resilience, and sustainability, polyurethane ICF is well-positioned to meet or exceed requirements:

- Already exceeds most energy code requirements in all climate zones

- Meets or exceeds structural requirements for high wind and seismic zones

- Provides built-in fire resistance that satisfies increasingly stringent safety codes

- Offers the airtightness required by modern energy codes without additional measures

Material Science Advancements

Ongoing research continues to improve polyurethane ICF technology:

- Enhanced fire-resistant formulations

- Bio-based polyols that reduce fossil fuel dependence

- Optimized molecular structures for even better thermal performance

- Advanced molding techniques for more precise and consistent forms

- Continued reduction in embodied carbon through manufacturing improvements

Conclusion: A Material Difference That Matters

The material science behind Monolith’s polyurethane ICF represents a significant advancement in building technology. By addressing the fundamental limitations of traditional building materials, it delivers measurable improvements in performance, efficiency, and resilience.

For builders and contractors, these material advantages translate to practical benefits: faster construction, reduced labor requirements, fewer weather delays, and enhanced quality control. For building owners, the superior performance of polyurethane ICF means lower operating costs, reduced maintenance, enhanced comfort, and better protection against disasters.

As the construction industry faces increasing challenges from labor shortages, extreme weather events, and more stringent building codes, advanced materials like Monolith’s polyurethane ICF provide a forward-looking solution. By combining the proven strength of concrete with the advanced properties of polyurethane, this system delivers not just incremental improvements but a fundamentally better approach to construction.

Ready to experience the material difference firsthand? Attend one of our upcoming workshops to see live demonstrations, including material testing that showcases the superior performance of polyurethane ICF. Learn how this advanced building material can improve your next project while providing access to exclusive Pioneer pricing available only to workshop attendees.